3D printing also known as additive manufacturing, consists in creating a three-dimensional object layer by layer by adding material, unlike conventional industrial processes such as milling, machining which are said to be subtractive because material is removed.

There are several additive manufacturing processes.

C3d uses that of the FDM (Fused Depositon Modeling) and CFF (Composite Filament Fabrication) type melted wire deposit.

This technique involves extruding a polymer filament from the high temperature heated print nozzle. The nozzle moves on three axes (X, Y, Z) according to the orders given by a digital file and thus reconstructs in successive layers a 3D model.

There are several additive manufacturing processes.

C3d uses that of the FDM (Fused Depositon Modeling) and CFF (Composite Filament Fabrication) type melted wire deposit.

This technique involves extruding a polymer filament from the high temperature heated print nozzle. The nozzle moves on three axes (X, Y, Z) according to the orders given by a digital file and thus reconstructs in successive layers a 3D model.

Everything starts with the design of the object via a CAD software, or via a 3D scan. The resulting 3D file contains all the data needed to obtain a printable 3D file.

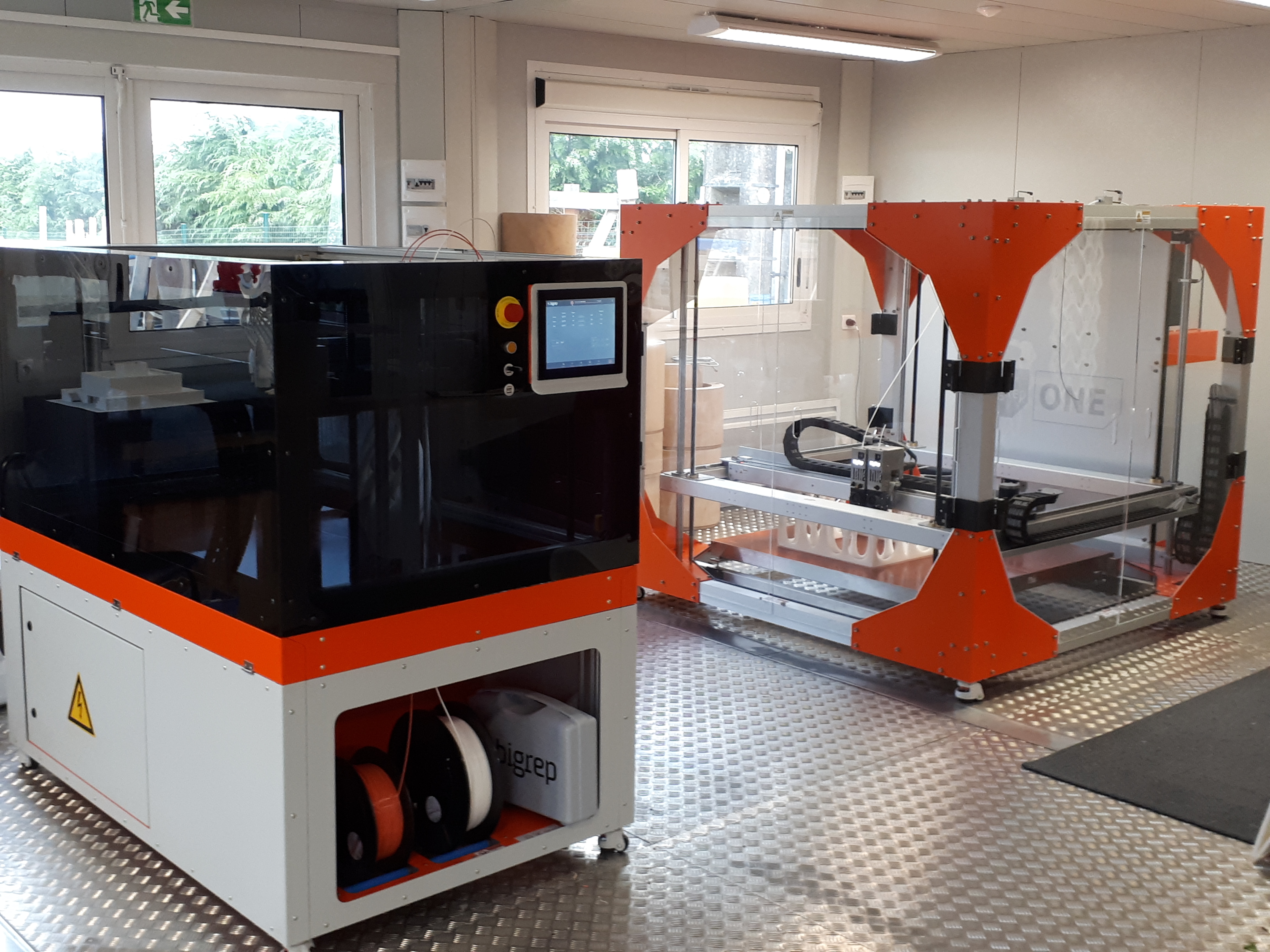

Our BIGREP ONE printer allows for high volume printing up to 1m3. Equipped with two extruders, it can combine several colors, several materials or make complex shapes through the use of supports.

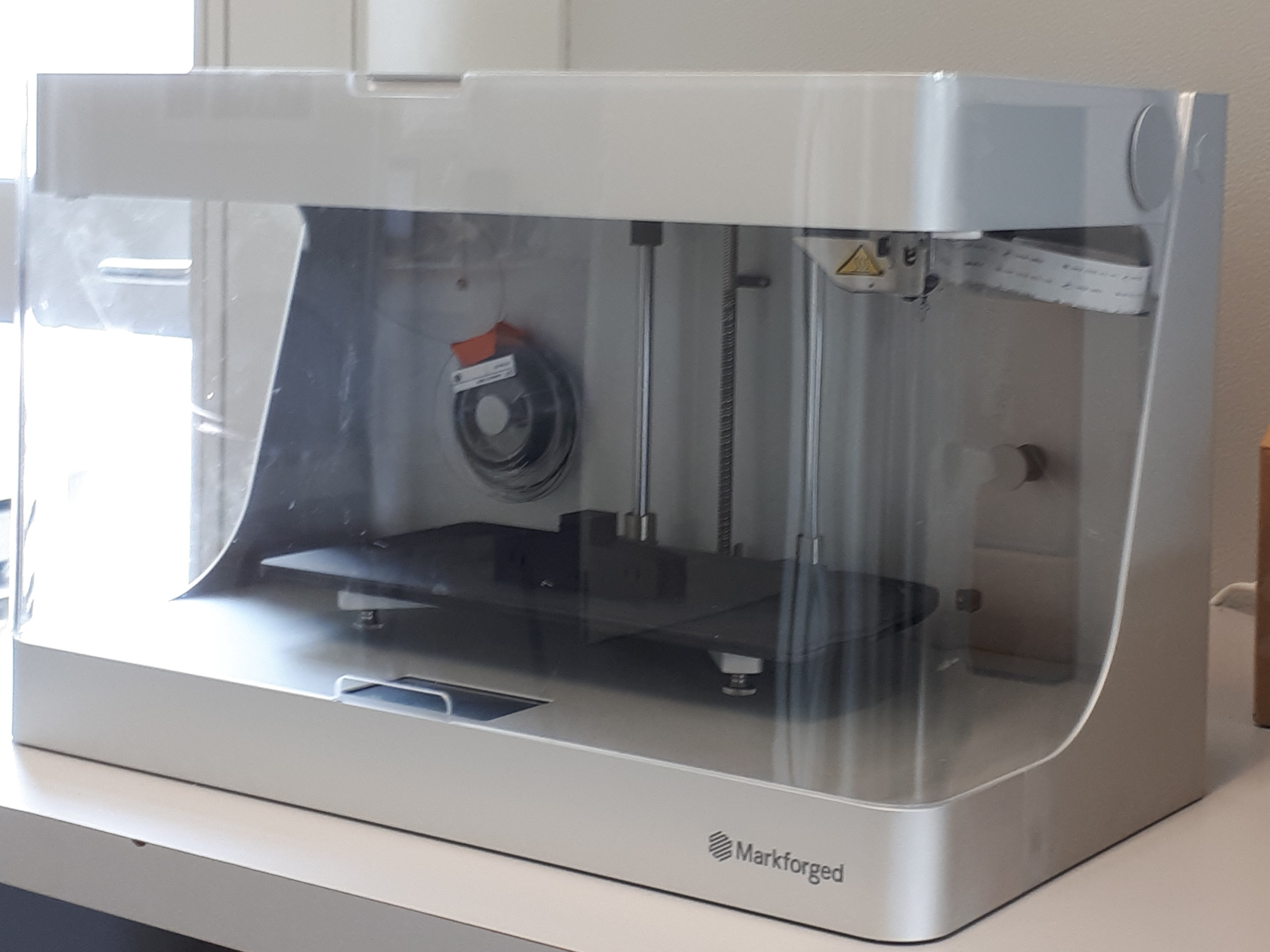

The MARKFORGED brand printer is based on continuous fiber reinforcement technology. The first nozzle extrudes a mixture of nylon and micro carbon fiber, while the second reinforces printing with carbon fibers or glass fibers or kevlar fibers. This technology gives rigidity and resistance to parts. The layer resolution being 100 microns.

C3d gives life to your ideas that take shape and volume.

Our BIGREP ONE printer allows for high volume printing up to 1m3. Equipped with two extruders, it can combine several colors, several materials or make complex shapes through the use of supports.

The MARKFORGED brand printer is based on continuous fiber reinforcement technology. The first nozzle extrudes a mixture of nylon and micro carbon fiber, while the second reinforces printing with carbon fibers or glass fibers or kevlar fibers. This technology gives rigidity and resistance to parts. The layer resolution being 100 microns.

C3d gives life to your ideas that take shape and volume.